How to Improve Asphalt Paving Profitability with Thermal Analysis

When it comes to accuracy in compaction and mix quality, the human eye and manual checks simply can’t produce enough data points to give a true picture of where a major issue can arise after paving: thermal segregation.

Thermal segregation simply means the opportunity for the freshly paved road to be improperly compacted due to mix temperature variables which results in premature deterioration and ultimately missing incentives or getting the dreaded disincentive for road quality.

With the proper technology, this can be quickly detected and corrected to have the best opportunity to deliver top-quality paving results.

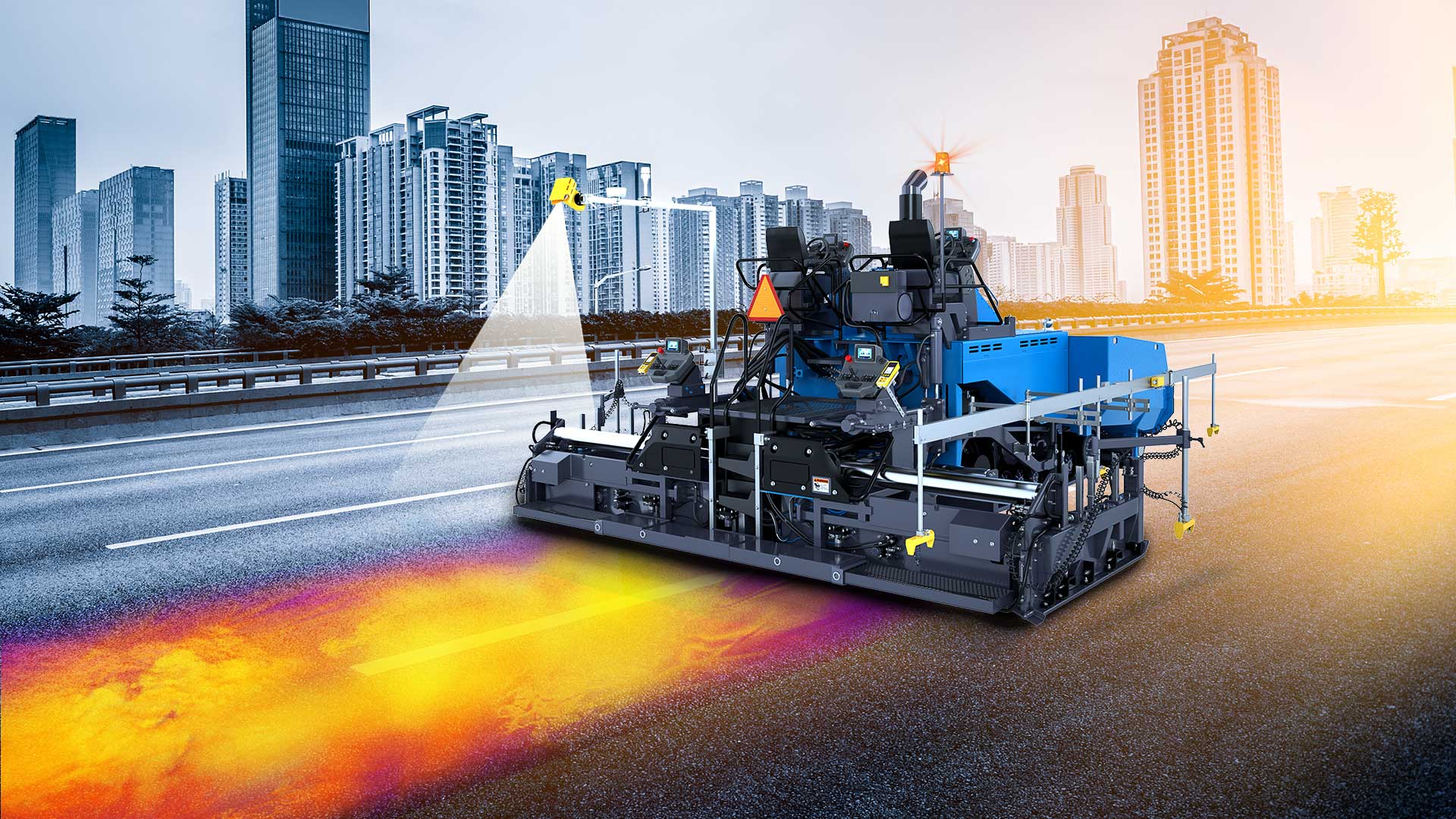

These factors are why MOBA pioneered thermal analysis and the Pave-IR system, to empower crews with the real-time information of live monitoring and providing backend reports. The Pave-IR system not only allows you to achieve high-quality roads but also delivers documentation of your work. Project data can be sent directly to the cloud and with Pave Project Manager and be thoroughly analyzed. Project reports can be generated to show your quality results to the road owner and lock in those bonuses.

When it comes to researching the best technology, a comprehensive thermal visualization of the paving process offers important insights regarding the quality of the material and introduces a completely new way to optimize the paving process. It’s a solution we’ve pioneered and have the depth of experience to partner with our customers to fully utilize.

If you’re ready to start combatting thermal segregation on your next job, contact our team today to ask questions and share details of your machine and job specs.

zurück zur Übersicht